|

|

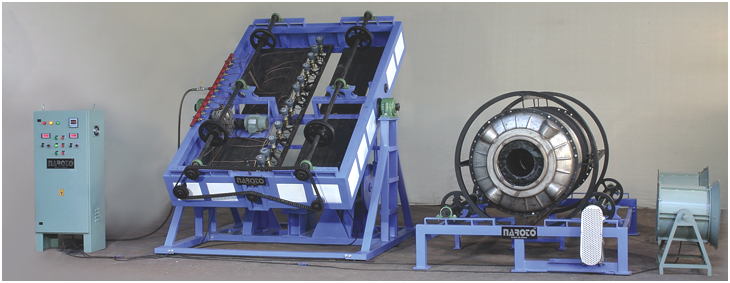

| Rock n Roll type Rotomoulding Machine | Rock n Roll Process | |||||||||||||||||

Now, the product is ready for sale.

WHY REQUIRE 3 ARM BI-AXIAL CLOSED OVEN ROTOMOULDING MACHINE INSTEAD OF OPEN FLAME ROCK N ROLL M/C.

|

|||||||||||||||||

|

|||||||||||||||||||||||||

|

|||||||||||||||||||||||||

|

|||||||||||||||||||||||||

| Copyright © 2007,N. A. Roto Machines & Moulds India All rights reserved | |||||||||||||||||||||||||